|

|  |

Mining Situation

The extraction of raw material by traditional mining will become more complicated in the future, because:

- The costs will increase related to more technical difficulties of the extraction

- The countries with raw material deposits are mainly in politically critical situations

- The countries where raw material is located will fight for a larger profit share

- The population of countries with raw material deposits will not accept an export of resources

- The population of countries will not accept a negative environmental impact

Therefore experts have already stated that the extraction of raw materials from seawater will become an alternative for the future, and actually the extraction of 5 materials will make sense from a technical and economical point of view. These materials are Natrium Chloride (salt), Magnesium, Calcium, Potassium and at last Lithium. Based on the actual technologies Lithium is the last one, where the extraction from seawater is sustainable. For materials with lower concentration than Lithium, for example uranium, the extraction from seawater makes actually no sense. The extraction of Uranium requires more energy than can be produced by the same material.

The extraction of raw material from seawater has been investigated for single products only, so that the whole production cost must be added to one product.

The Multiprocessing production includes the extraction of all materials which can be extracted technically and economically from seawater in only one production line. It means that the extraction of all materials is possible with partially the same energy and production costs like for one material. Also the Multiprocessing production creates many synergy effects like the use of thermal energy as by-product of the electricity generation, and eliminates waste, because all materials which are extracted will be converted into valuable products. Multiprocessing is not only a raw material production because all extracted materials from seawater (for example salt) are processed in a further production to final products or intermediary products of high value.

Actual situation of magnesium production

Magnesium is a light weight metal material, 25% more light than aluminum, with excellent features for stability. According to this features it is a favorite material for all kinds of mobile products, like cars, smartphones, notebooks, etc.

Magnesium parts have already been tested with positive results by the car manufacturer and have been introduced into the production of high tech cars, which are produced in smaller quantities, to lower the weight of the cars.

Actually magnesium parts will not be used in the mass production of cars because of two restrictions:

- The price of magnesium on the world market, which is dominated by Chinese producers, is too low to make an investment in magnesium production attractive in countries outside of China.

Missing investments in additional capacities, because of low magnesium prices, prevent the industry from the use of magnesium in an industrial mass production. On the other hand the price of magnesium is too high to compete with aluminum. A price equal to aluminum would open the door for magnesium for the mass production because the material is 25% lighter than aluminum. - The CO2 emission of the usual magnesium production processing is high because of the large power consumption which the processing requires.

Our new Multi-Processing production of magnesium will change completely the actual situation, which prevents magnesium from an industrial mass production.

The core of our Multi-Processing is the production of many valuable products from the same raw material which requires lower production costs and lower energy consumption as it is needed for a single magnesium production.

Lithium the “crude oil” of the next century

When the electrification of the transportation system, which has already started, will speed up, and increasing numbers of vehicles will be driven by electric engines, Lithium will become an important material for the production of batteries. Therefore experts have already mentioned that Lithium will be the oil of the next century.

Finally the electrification can lead to a scenario where the demand of Lithium will be higher than the supply from the existing resources. In such a situation the extraction of Lithium from seawater will be the only solution to solve this problem, because Lithium is number 5 on the list of elements which are contained in the seawater and can be extracted by economic processing. Though the concentration of Lithium in the seawater is low, the total amount of Lithium in the seawater is large enough to meet the demand for a very long time.

The extraction of Lithium requires much more energy than the extraction of Magnesium, but on the other hand the price of Lithium is much higher than the price of Magnesium. Actually the raw material for the production of Lithium carbonate is extracted from salt lakes mainly in South America where the natural solar energy is used for an up-concentration. The reserves of this lakes are limited and when the electrification of cars will speed up, the demand may exceed the supply. Therefore experts are stating that the extraction from seawater will be the only solution for the future to meet the rising demand.

For our Multiprocessing the production of Lithium makes sense, because we are already using seawater as raw material for our magnesium production. Therefore a part of up-concentration is already done and the Lithium production will increase the synergy effects of our Multiprocessing Production. Another advantage is that we are already producing materials which are necessary for a production of pure Lithium by our chlorine-alkali-electrolysis. We don`t need to purchase and transport this materials from somewhere in the world.

Instead of natural solar energy we will operate the evaporation process with thermal energy which is available as by-product from our power generation. For the Lithium production from seawater it is not possible to operate only with evaporation because of the very low concentration of Lithium in seawater.

Therefore it is necessary to operate with a combination of different processes. The first process can be evaporation followed by ion exchange and electrolysis. Another solution will be the separation of Lithium by an adsorbant. In special areas of the sea the Lithium content in sediments on the bottom of the sea is much higher than normal in seawater. It can make sense to start with a Lithium production from the sediments and, because the resources in sediments are not endless, switch over to a Lithium production from seawater in steps. With this kind of production there will be enough time to find out the best combined processing for the Lithium production from seawater.

A Lithium production from seawater guarantees huge resources of raw material and makes the production independent from any raw material market. With an integrated Lithium production as part of our total production range our Multiprocessing based on seawater as raw material becomes a perfect production system, which generates a lot of synergy effects.

Description of “Multi-Processing”

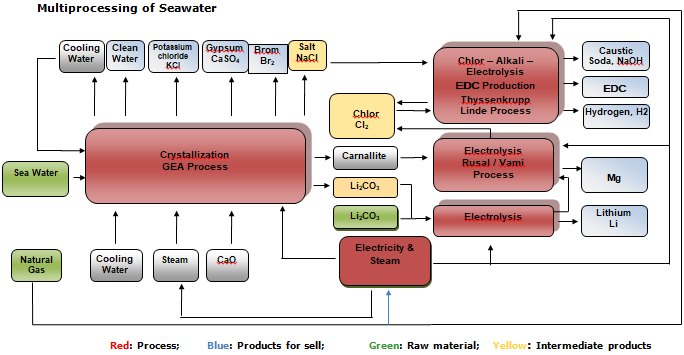

For the Multi-Processing Production different and experienced processes from major large companies are used:

- Evaporation process by GEA, a German expert for crystallization and evaporation. A preliminary upgrade of the magnesium and Lithium concentration in seawater for the production of carnallite (basic material for the magnesium production process) and Lithiumcarbonate (basic material for the Lithium production process) is necessary.

- Magnesium electrolysis process by Rusal/Vami, a Russian company, which is the largest alumina producer worldwide and the leading company worldwide with activities in the magnesium electrolysis.

- Power generation based on natural gas or solar-thermal resources, for the production of steam and electricity to serve the processes with the required energy with very low CO2 emissions. The electricity and thermal power generation will be installed and provided by Siemens, our partner for power generation with a long term experience in the power production from different fuels.

- A chemical production process combination by Thyssenkrupp industrial solutions and Linde converting our basic raw material salt, which will be produced by the GEA process, and our chlorine gas into chemical products of much higher value.

- A Lithium production process to convert Lithium Carbonate into Lithium Cloride and after into pure Lithium by electrolysis. Rusal, in cooperation with potential partners, is interested to provide the technology for this kind of processing.

Each of this companies has already used its technology for production plants in the world, and therefore the processes are approved and experienced.

In the combined production of Multi-Processing the single processes of all the companies are not changed or mixed up in any kind, they are used like in a single process, but connected in series combined in a large total production. Therefor each of the processes will operate in a “stand alone” manner without any additional risk and will not be interfered by the following process.

All companies, Siemens, GEA, Rusal/Vami, Thyssenkrupp industrial solutions and Linde will be partner companies for the development, engineering, construction until the operation. The partner companies are leaders in their technology and in their business field.

Special cooperation agreements related to the development, engineering and construction of Multiprocessing Projects have already been made between the industrial partner and the project leader, the company Hoffmann Financial Consulting, which is responsible for the coordination of all activities regarding the project, especially during the project development phase, in order to develop a project, which is bankable.

Hoffmann Financial Consulting is also responsible for the financing of the Multiprocessing Projects, and has already established contacts to banks and financiers who are interested in the financing of the projects.

This potential financing partner will be parallel informed about the results of the project development and by their statements they have an influence in the project development.

Multiprocessing Process with 3 major advantages:

- From the technical point of view we will use a combination of experienced processes, for example a evaporation process by GEA, an electrolysis process by Rusal/Vami, chemical processes by Thyssenkrupp industrial solutions and Linde. All companies are leaders in their business fields and have already implemented their process-technologies in existing plants, which are still operating without any problems. Therefor we will have no process risk.

- From the environmental point of view we are using seawater as an uncritical raw material, available in endless quantities, for our processing, without rejecting any kind of brine back to the sea. The actual desalination plants are producing a brine, which is rejected back to the sea and creates environmental problems in the region. Our salty material is used as raw material for our processing, and by our multiprocessing we will extract all components which are contained in the salty brine. Finally we will get a number of different materials, used for our further processing, and no brine is left and rejected back into the sea.

By our Multi-Processing we will produce many valuable products from the same raw material and with energy, which is provided from natural gas. Therefore the CO2 emissions will be very low, and divided through all different products the CO2 emission for magnesium produced by our multiprocessing will be a new world record. - From the economic point of view our production costs for magnesium and other products by our Multi-Processing are lower than they would be in a usual single production. Because the revenues of our by-products compensate most of the production costs, including the financing costs, we are able to produce magnesium, Lithium and water by our Multi-Processing on a low cost level.

Our Multi-Processing guarantees the lowest production costs and the lowest CO2 emissions for a magnesium production worldwide.

CO2 Emission of different Magnesium Productions compared

with our new Multiprocessing Production

|

Magnesium Production Process (Location) |

Electrical Energy Source |

GWP, kg/kg |

GWP, with by-product credits, kg/kg |

|

|

Magnesium Production Processes |

|

|

|

|

|

Thermal |

Bolzano (Brazil) |

13,8 |

No by-products available |

|

|

Magnetherm (France)** |

17,6 |

|||

|

Pidgeon (China) |

43,3 |

|||

|

Electrolytic |

Norsk Hydro (Canada)** |

16,1 |

||

|

AM (Australia)** |

27,9 |

|||

|

Multi-Processing |

Natural Gas |

10,5 |

6,6 |

|

|

Electrolytic |

Multi-Processing |

Gas/Solar-thermal |

6,1 |

2,3 |

|

Aluminium Production Process |

|

|

|

|

|

Electrolytic |

Prebaked Anode Technology |

Coal |

17,6 |

No by-products available |

** Planned Production

Benefits for the Investors

The investors will benefit from the low production costs of the Magnesium and Lithium Multi-Processing, which will be the lowest worldwide. With the production of 50.000 tons of magnesium in a country outside of China the magnesium plant has a major influence in the magnesium market, because the magnesium production outside of China is rather small. No existing magnesium production can compete with our magnesium price equal to aluminum. The start capacity of the Lithium production with 1.800 tons per year can be increased because of the huge Lithium resources in the seawater.

Benefits for the Country

The country which will be the location for the plant will profit from the project in a multiple way:

- The project will create many new jobs in a high tech production.

- The Multi-Processing production will be a highlight in the magnesium and Lithium production and in the seawater desalination.

- By Multi-Processing potable water production is possible without any brine as waste material and at very low production costs. Therefor subsidies of the states for water can be reduced or avoided.

- The CO2 emission for each single product of the Multi-Processing is lower than in any other production.

- By Multi-Processing the magnesium production in countries out of China is able to compete with the production costs in China and therefore the magnesium production in western countries will have a renaissance.

- It is usual that industries and productions, which are based on primary magnesium will be implemented nearby the magnesium raw material production in order to cut transportation costs and to save energy by using the already melted magnesium from the primary magnesium production.

- A magnesium sheet production based on primary magnesium is already in discussion to save energy by using the liquid magnesium. Such an additional production will increase the product value and create new jobs.

The country, which will support the project will become a leading country in the magnesium production and water desalination on an environmental friendly basis.

Preliminary Economic Numbers of our Magnesium & Lithium Multiprocessing Production:

|

Investment |

3,400,000,000 USD |

Revenues

|

By-Products |

1,196,569,964 USD |

|

Mg & Lithium |

336,000,000 USD |

|

Total |

1,532,569,964 USD |

Our Multi-Processing magnesium production will be a milestone project and will open the door for the use of magnesium as major light weight material in an industrial mass production.

It will produce new benchmarks for an environmental friendly and cost effective production of magnesium.

By our multiprocessing we are in a position to offer our magnesium at a price level equal to aluminum and with lower CO2 emissions related to the production than for the production of any other material like aluminum, steel, carbon.

Especially the car industry is waiting for such a situation to introduce magnesium in the mass production of their products.

Large car producer of the world have already shown an interest in our magnesium produced by our multiprocessing.

The availability of all necessary materials and also energy at a low price level at the same location is a big advantage for our multiprocessing production.

The broadband of the produced products increases the stability of revenues against the volatility of the markets.

Our Multiprocessing is not only a new highlight for the production of magnesium, it is also a new highlight for the water desalination.

By our multiprocessing it is possible to produce potable water without any brine or other kind of waste which actually will be rejected back to the sea.

But the largest benefit of our potable water production is the fact that we are able to produce potable water at the price level of typical ground water and therefore state subsidies for the water tariffs can be reduced or avoided.

The standard co-generation of potable water and electricity only will not be able to offer potable water at such low price levels because beside electricity and water there no other products by which the less revenues from the potable water can be compensated.

The Lithium production, which will complete our Multiprocessing, offers new ways of production for a very important material which is characterized by limited resources on the landside.